Every year, millions of people around the world take pills that aren’t what they claim to be. Fake drugs don’t just fail to work-they can kill. A fake medicine might contain the wrong dose, toxic chemicals, or nothing at all. In low- and middle-income countries, the World Health Organization estimates that 1 in 10 medical products is counterfeit or substandard. That’s not a distant threat. It’s happening in pharmacies, online stores, and even hospitals. The good news? The tools to stop it are evolving faster than ever.

What’s Changing in Drug Security?

The biggest shift isn’t just about adding fancy labels. It’s about giving every single pill, bottle, or vial a digital fingerprint. This is called serialization. By 2025, the U.S. Drug Supply Chain Security Act (DSCSA) and the EU’s Falsified Medicines Directive (FMD) require every prescription drug package to have a unique code. That code isn’t just a barcode-it’s tied to a secure database that tracks the product from factory to pharmacy. If a bottle doesn’t match the system, it’s flagged before it reaches you.Before serialization, recalls took weeks. Now, with unit-level tracking, companies can pull a bad batch in hours. One major distributor cut recall time by nearly 60% after switching to full serialization. That’s not just cost savings-it’s lives saved.

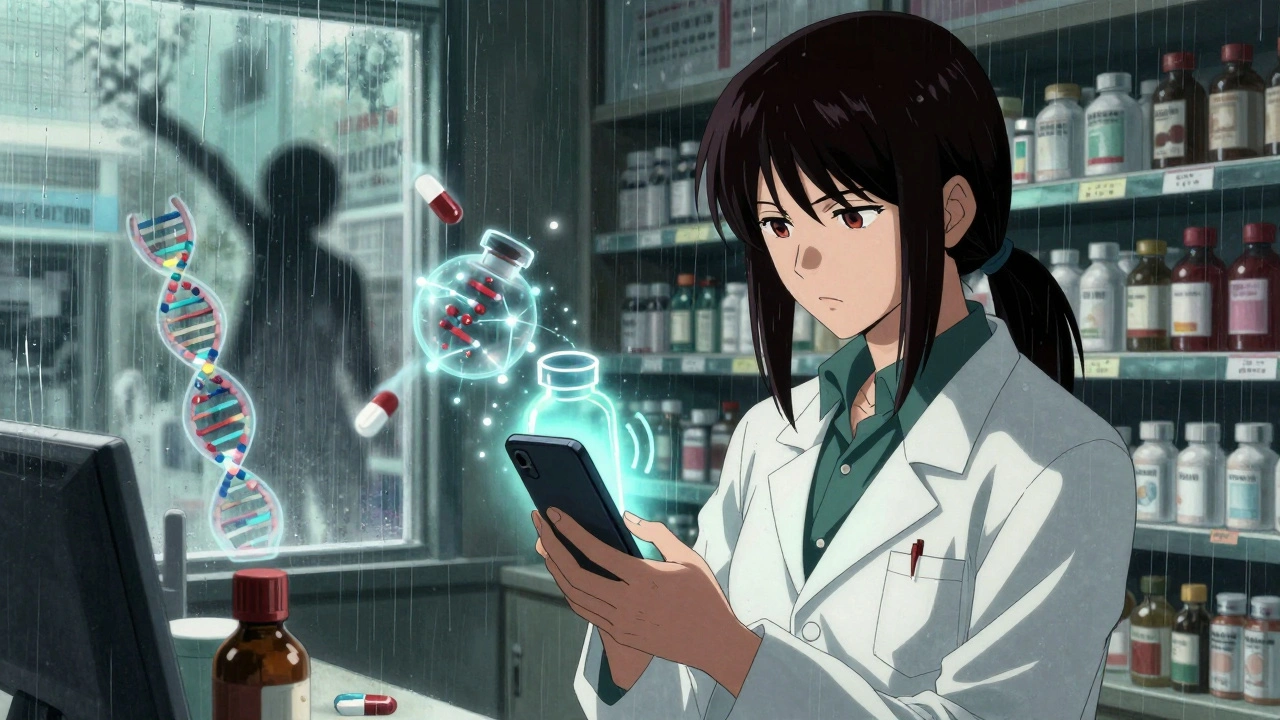

NFC: The Smartphone That Checks Your Medicine

You don’t need a lab to verify a drug anymore. Just tap your phone.Near Field Communication (NFC) chips are being embedded into medicine packaging. These tiny chips hold encrypted data that can’t be copied. When you tap your phone-Android 8.0+ or iOS 11+-the app instantly checks the product against a secure registry. The whole process takes under two seconds. Accuracy? 99.98%, according to real-world tests at CPHI Frankfurt in 2025.

Why is this better than QR codes? Because QR codes can be printed and stuck on fake bottles. In fact, 78% of pharmaceutical QR systems failed security audits in 2025 because they weren’t encrypted. NFC, on the other hand, uses cryptographic authentication. A Latin American pharmacy chain saw a 98% drop in counterfeit incidents within six months of switching to NFC. Pharmacists now verify over 1,200 products a day-adding just 3 to 5 seconds to each sale.

Blockchain: The Unbreakable Ledger

Think of blockchain as a digital notebook that no one can erase or fake. Every time a drug moves-from manufacturer to wholesaler to pharmacy-it’s recorded on this shared ledger. Temperature, humidity, location, and time are all logged. If the cold chain breaks during shipping, the system knows. If someone tries to inject a fake batch into the system, the mismatch shows up immediately.Companies like De Beers used blockchain to track diamonds. Now, pharma is doing the same. The technology isn’t just about tracking-it’s about trust. Regulators demand proof of origin. Blockchain delivers it. But it’s not easy to set up. Gartner says full blockchain integration takes 18 to 24 months. That’s why most big companies start with serialization first, then layer blockchain on top.

DNA Markers and Forensic Inks: The Invisible Shield

Some of the most advanced defenses are invisible. DNA-based authentication embeds a unique biological code into the packaging or even the pill coating. To verify, you need a special scanner-like a forensic lab in a box. It’s nearly impossible to replicate. But it’s expensive: $0.15 to $0.25 per unit. For mass-market drugs, that’s not feasible.More common are covert inks. These change color under UV light, disappear at certain temperatures, or only show up under infrared. They’re cheap, easy to apply, and hard for counterfeiters to copy without knowing the exact formula. Holograms with microtext and guilloche patterns are still widely used too. They’re overt-visible to the naked eye-but designed to be impossible to reproduce with a printer.

AI Vision Systems: The Digital Inspector

At the end of the line, before a drug reaches you, it’s inspected. That’s where AI-driven visual inspection comes in. Cameras scan every package as it moves through the warehouse. AI compares the label, font, color, and even the texture of the foil against a digital twin of the real product. In controlled labs, these systems detect fakes with 99.2% accuracy.Real-world use is trickier. Lighting, packaging damage, and dirt can confuse the system. But accuracy jumped from 89.7% in 2024 to 94.3% in mid-2025. Companies like Cognitivemarket are rolling out these systems in high-risk markets. They’re not replacing humans-they’re giving them a second pair of eyes.

Why Some Solutions Are Failing

Not every high-tech fix works. A major U.S. drugmaker launched a QR code system in 2024 without encryption. By Q3 2025, fraudsters had copied the codes, printed them on fake bottles, and flooded the market. The result? A $147 million recall. The lesson? If the code isn’t cryptographically locked, it’s useless.Another problem? Cost. Small manufacturers struggle to afford serialization equipment. Training staff, upgrading servers, and integrating with ERP systems can cost millions. One European distributor spent €2.3 million and lost 37% of warehouse throughput during their 14-month rollout. That’s why adoption among small pharma companies is still only 43%.

And then there’s the supply chain chaos. In April 2025, new U.S. tariffs on pharmaceutical imports from China and India hit 10% to 46%. Production costs rose 12% to 18%. Delivery delays stretched to 45 days. That’s putting pressure on companies to cut corners-and making counterfeiters’ jobs easier.

What’s Next? The Future Is Multi-Layered

No single technology is enough. The future is stacking defenses. A single bottle might have:- A visible hologram

- An NFC chip

- A QR code linked to a blockchain record

- UV-reactive ink

- A DNA marker in the coating

By 2027, 83% of pharmaceutical executives say they’ll use this kind of multi-layered approach. The EU’s new Digital Product Passport rule, requiring every package to link to a digital profile of its entire lifecycle, will push this even further.

Meanwhile, material science is catching up. Over 60% of new anti-counterfeit packaging now uses recyclable materials. The goal? Security without waste. You shouldn’t have to choose between safety and sustainability.

What You Can Do

As a patient, you don’t need to be a tech expert. But you can be smart:- Buy from licensed pharmacies-online or in person.

- Use your phone to scan NFC tags on new prescriptions.

- Check if the packaging looks off: mismatched fonts, blurry logos, or missing seals.

- Report anything suspicious to your pharmacist or health authority.

Counterfeiters are getting smarter. But so are the tools fighting them. The race isn’t over-but for the first time, the good guys have the upper hand.

Michael Robinson

December 7, 2025 AT 23:37It’s wild to think that the medicine you swallow could be a fake. I used to think this was just a third-world problem, but now I see it’s everywhere. If your heart pill doesn’t work because someone printed a fake label, that’s not just negligence-it’s violence. We treat cars like they need 100% verification, but our lives? We just trust the bottle.

Maybe the real problem isn’t the tech-it’s that we’ve stopped caring enough to demand better.

Kathy Haverly

December 9, 2025 AT 05:03Stop hyping this. All this ‘NFC’ and ‘blockchain’ nonsense is just corporate theater. The real reason fake drugs exist is because Big Pharma prices life-saving meds so high people are desperate enough to buy off Amazon. This tech just lets them charge more while pretending they care.

Also, ‘DNA markers’? That’s just sci-fi buzzwords for ‘we’re selling you a sticker that costs 25 cents’.

Andrea Petrov

December 10, 2025 AT 01:53Have you ever wondered who owns the blockchain ledger? Because if it’s a private company, then they’re not protecting you-they’re profiling you. Every scan of your pill? Logged. Tracked. Sold. This isn’t safety, it’s surveillance capitalism with a pill bottle.

And don’t get me started on ‘AI vision systems.’ Those cameras are trained on Western packaging. What about the guy in Lagos who buys medicine in a plastic bag? His fake pill gets flagged as ‘real’ because the AI doesn’t recognize his packaging.

They’re not stopping fakes. They’re making the poor invisible.

Suzanne Johnston

December 11, 2025 AT 20:48I appreciate the depth here, but I think we’re missing the human layer. All these technologies mean nothing if pharmacists are overworked and patients are too scared to ask questions. I worked in a clinic in rural Kentucky last year-we had zero NFC tech, but we had trust. We knew our patients. We knew their meds.

Maybe the real solution isn’t more tech, but more time, more training, more compassion. You can’t scan empathy into a system.

Also, I’m glad they’re using recyclable materials. That’s the quiet win here.

Graham Abbas

December 12, 2025 AT 02:14Okay, I’m genuinely moved. This isn’t just about pills-it’s about dignity. Imagine being sick, scared, and then realizing the thing you’re taking to live might be killing you. That’s a horror story no movie dares to tell.

And the part about small manufacturers? That’s the tragedy. They’re not villains-they’re just trying to survive. We need subsidies, not just regulations. We need to lift them up, not punish them.

Also, I just scanned my blood pressure med with my phone. It verified in 1.7 seconds. I cried. Not because it’s cool tech-but because for the first time, I felt safe.

Haley P Law

December 12, 2025 AT 17:21OMG I JUST SCANNED MY ANTIBIOTICS AND IT WAS REAL 😭😭😭 I’M CRYING RN LIKE THIS IS A ROM COM OR SOMETHING

Also can we talk about how the hologram on my bottle looked like a unicorn? WHO DESIGNED THAT??

Also also I just reported a sketchy website that sold me ‘Vicodin’ for $3. I’m a hero.

Andrea DeWinter

December 13, 2025 AT 09:14One thing people don’t mention is how hard it is for elderly folks to use NFC apps. My grandma can’t even open her email without help. So now we’re giving her a ‘secure’ pill bottle and telling her to tap her phone? That’s not safety-that’s exclusion.

They need simple stickers with a phone number to call. No apps. No QR codes. Just a voice on the line saying ‘yes your pill is real.’

And yes I’ve called that number. It works.

Chris Marel

December 13, 2025 AT 17:00Back home in Nigeria we’ve been dealing with fake drugs since before most of you were born. We used to check the color of the pill, smell the bottle, feel the texture. We learned because we had to.

Now I see all this fancy tech and I’m happy-but I’m also sad. Why did it take so long for rich countries to care? We’ve been dying quietly for decades.

Let’s not forget the people who can’t afford phones. Tech should help everyone-not just those with the latest iPhone.

Nikhil Pattni

December 14, 2025 AT 21:15Actually you guys are all missing the point. Serialization is just a band-aid. The real solution is mandatory real-time AI-driven blockchain-enabled DNA-tagged nano-sensors embedded in every pill with quantum encryption synced to a decentralized global registry with zero-trust authentication and biometric verification of the prescriber AND the patient AND the pharmacist AND the delivery drone AND the ambient temperature of the storage unit during transit. Also, the bottle should be made of graphene-infused bioplastic that self-destructs after 72 hours if not scanned. And yes I’ve read the EU directive. I’ve also read the Gartner report. I’ve consulted with three CTOs. You’re all just amateurs.

Elliot Barrett

December 14, 2025 AT 23:34This whole post feels like a corporate press release. NFC? Blockchain? AI? Cool. But where’s the data on actual lives saved? Show me the numbers. Not ‘99.98% accuracy’-show me how many people didn’t die because of this.

Also, why is no one talking about the fact that 80% of fake drugs are sold online? You think a QR code stops a scammer on Instagram?

Tejas Bubane

December 16, 2025 AT 11:50LOL so now we’re trusting tech from companies that got caught selling opioids to toddlers? You really think the same people who made this system are gonna protect you? Nah. They’re just making it harder for you to buy cheap generics. This isn’t safety. It’s profit in a lab coat.

Ajit Kumar Singh

December 17, 2025 AT 06:26India has been making generic medicines for the world for decades and now you come here with your NFC chips and DNA markers like we are some kind of backward village? We have over 2000 pharma companies producing 20% of the world’s generic drugs. We don’t need your fancy labels to make safe medicine. What we need is fair pricing and an end to your tariffs that make our medicine unaffordable. This isn’t about fakes-it’s about power. And you’re the ones holding the gun.

Maria Elisha

December 17, 2025 AT 13:33Okay but like… can we just… not? I’m tired. I just want my medicine to work. Why does everything have to be a tech revolution? Can’t we just… have better inspections? And maybe… not charge $500 for a blood pressure pill?

Also I bought my last refill at Walmart. It was fine. I didn’t scan anything. I’m still alive.

Jennifer Blandford

December 19, 2025 AT 12:06This is the most hopeful thing I’ve read all year. Not because of the tech-but because people are finally trying. We’ve been ignoring this for too long. I’ve got a friend in Puerto Rico who got sick from fake insulin. She’s okay now. But she shouldn’t have had to go through that.

Let’s not celebrate the gadgets. Let’s celebrate the fact that we’re finally listening. Even if it’s messy. Even if it’s slow. We’re moving.

And hey-thanks for the recyclable packaging bit. That’s the quiet revolution.